As you saw in the previous post, this crooked cabby is a mess. To see what we can use, we first have to clean it all up and test a few things. Cleaning not only helps to allow us to see the components and evaluate for damage easier but it also allows components to breath reducing heat which drastically reduces hardware fatigue and prevents fires. To see what we had, we tested the power and monitor with the existing harness and a test pattern generator and found that we had a working monitor, so we were already ahead.

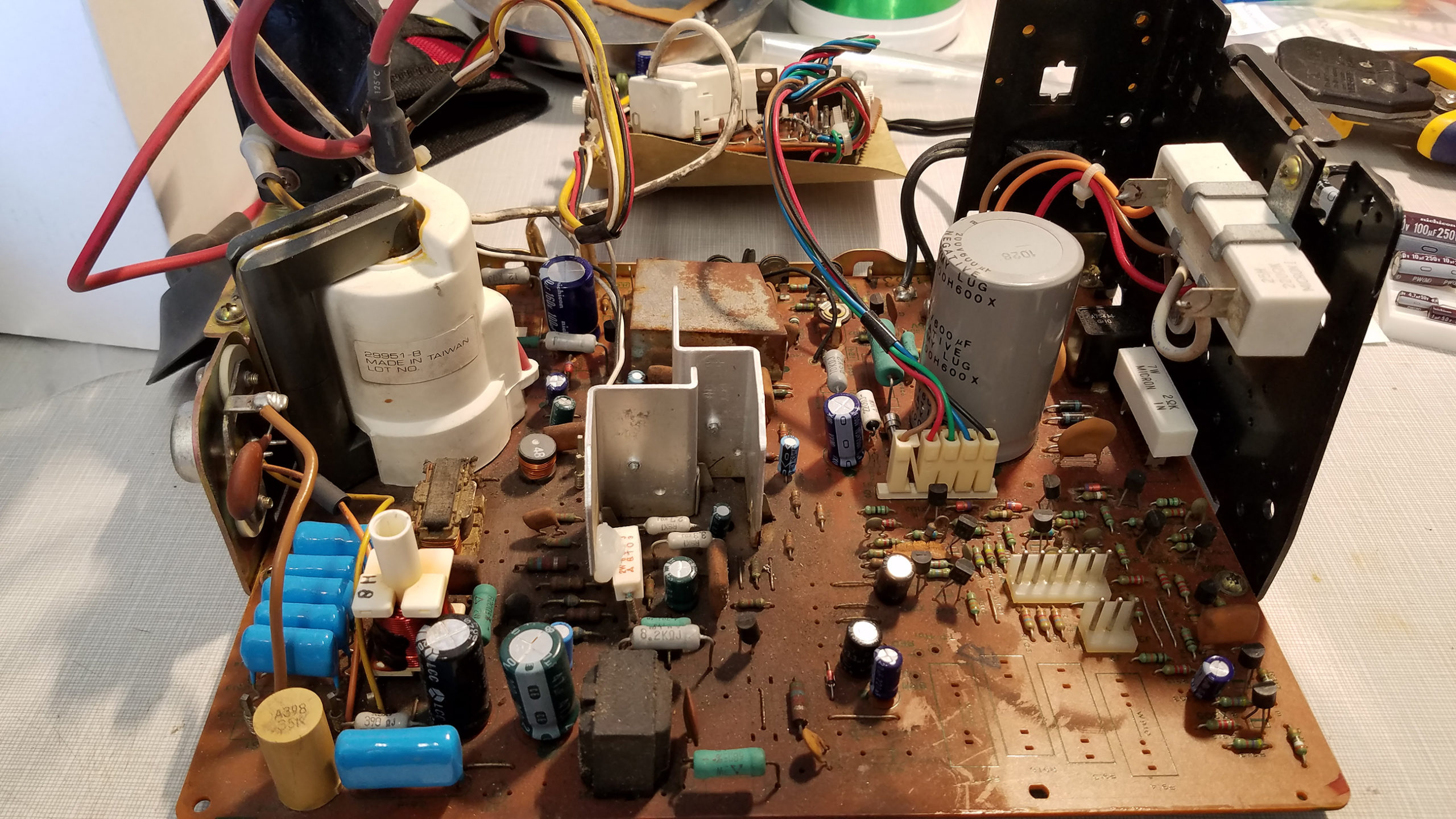

Now that we knew we had power and a working monitor we started clean-up. We started off cleaning up the power brick in the bottom which contains the isolation transformer for the monitor, the main fuses, and several other components used for power production. We then cleaned the monitor with some degreasing cleaner and a water hose. Then we replaced the more than 30-year-old capacitors on the monitor chassis. The cabinet needs a lot of work, so it will be a while before everything gets back in the cabinet securely.